A Vehicle Identification Number (VIN) search for heavy equipment provides a comprehensive history check, including manufacturer, model, production year, serial numbers, and reported incidents. This tool empowers operators to make informed decisions, enhance safety, minimize downtime, and improve operational efficiency in infrastructure projects. VIN searches offer valuable insights into equipment condition, maintenance records, and past accidents, enabling buyers to negotiate better prices and choose reliable brands for successful project execution with a focus on safety.

In the ever-growing infrastructure sector, ensuring the reliability and safety of heavy equipment is paramount. This is where a Heavy Equipment Vehicle Identification Number (VIN) Search emerges as a powerful tool. By conducting a VIN search, operators and buyers can access a wealth of information about machinery performance, manufacturing quality, and potential issues. This article delves into the significance of this process for both professionals, highlighting how it contributes to enhanced safety and efficiency in ambitious infrastructure projects.

- Understanding VIN Search for Heavy Equipment

- Benefits for Heavy Equipment Operators

- Value for Buyers through VIN Analysis

- Uncovering Manufacturing Details with VIN

- History of Incident Reporting and VIN

- Safety and Efficiency in Infrastructure Projects

- The Role of VIN Search in Machinery Reliability

Understanding VIN Search for Heavy Equipment

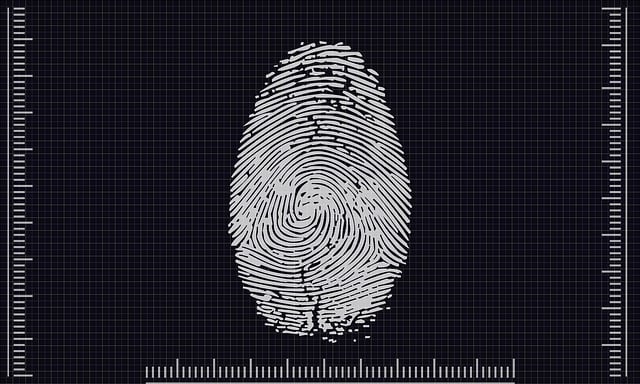

A Vehicle Identification Number (VIN) search for heavy equipment is a powerful tool that provides insights into a machine’s history and condition. It’s like having an extensive background check for a piece of machinery, revealing key details that can impact its performance and safety. The VIN, unique to each vehicle or piece of equipment, acts as a digital fingerprint, allowing operators and buyers to access a wealth of information. This includes the manufacturer, model, production year, and various serial numbers, all of which are crucial for identification and tracking.

Beyond basic specifications, a VIN search offers critical insights into any reported incidents or accidents related to the equipment. This is vital for heavy machinery, often used in demanding infrastructure projects where reliability and safety are paramount. By understanding past issues, operators can proactively address potential hazards, ensuring smoother operations and reducing downtime.

Benefits for Heavy Equipment Operators

For heavy equipment operators, conducting a Vehicle Identification Number (VIN) search is a game-changer. This simple yet powerful tool provides them with vital insights into their machinery’s history. By inputting the unique VIN code, operators can access a wealth of information, including the machine’s original manufacturer, year of production, and detailed specifications. Moreover, this process reveals any maintenance records, service histories, and, crucially, reported incidents or accidents associated with that specific piece of equipment. Such transparency empowers operators to make informed decisions, ensuring they are aware of potential issues before setting out on a job, thus enhancing safety and minimizing unexpected breakdowns.

Additionally, VIN searches offer operators a competitive edge in the market. Understanding the machinery’s past performance and maintenance track record allows them to negotiate better prices when buying used equipment. It also enables them to identify reliable brands and models, leading to improved operational efficiency and reduced downtime. In the fast-paced world of infrastructure development, where projects are often time-sensitive and cost-intensive, having access to such comprehensive information is invaluable.

Value for Buyers through VIN Analysis

For buyers in the heavy equipment market, conducting a Vehicle Identification Number (VIN) search is a powerful tool that offers numerous advantages. This process provides an in-depth look at the history and condition of machinery before purchase, ensuring investors make informed decisions. Through VIN analysis, buyers can uncover essential details such as the manufacturer, model, production year, and serial number—all critical factors when evaluating equipment for a construction project.

Moreover, this search reveals any reported incidents or accidents associated with the specific unit, allowing buyers to assess potential risks and maintenance needs. By gaining access to such comprehensive information, buyers can make strategic choices, acquire reliable machinery, and ultimately contribute to the success of their infrastructure projects while prioritizing safety and operational efficiency.

Uncovering Manufacturing Details with VIN

Every heavy equipment vehicle or machine has a unique Vehicle Identification Number (VIN), which acts as a fingerprint, providing an invaluable source of information about its origin and history. By conducting a VIN search, operators and buyers can uncover a wealth of details that shed light on the machinery’s manufacturing process. This includes the manufacturer, production year, model specifications, and even the exact facility where it was assembled.

Accessing this data is particularly beneficial for ensuring equipment authenticity and quality. It allows professionals to verify if the equipment has been properly maintained, serviced, and repaired over its lifespan. Moreover, it helps in identifying any potential issues or defects associated with specific production batches, enabling buyers to make informed decisions and maintain high safety standards on their projects.

History of Incident Reporting and VIN

The practice of incident reporting has evolved significantly over time, driven by a growing need to ensure safety and accountability in various industries, including construction and heavy equipment operation. Historically, tracking incidents and accidents was often done through manual record-keeping, which could be inconsistent and challenging to access. This changed with the advent of vehicle identification numbers (VIN), which were initially introduced for automotive purposes but later adapted for heavy machinery.

VIN structures provide a unique identifier for each piece of equipment, allowing operators and buyers to access detailed information about its manufacturing, history, and any reported incidents. This evolution has been crucial in enhancing safety standards and efficiency in infrastructure projects. By conducting a comprehensive VIN search, professionals can gain valuable insights into the past performance and maintenance records of heavy equipment, enabling them to make informed decisions that contribute to project success while prioritizing operator safety.

Safety and Efficiency in Infrastructure Projects

In infrastructure projects, safety and efficiency go hand in hand. Heavy equipment plays a pivotal role in these endeavors, from constructing bridges to developing transportation networks. However, relying solely on visual inspections or traditional methods of tracking equipment can leave gaps in understanding their true condition and history. This is where conducting a Heavy Equipment VIN Search becomes indispensable.

By employing VIN Structure Analysis, operators and buyers gain access to a wealth of information that enhances safety measures. It allows them to identify potential hazards associated with specific machinery, such as structural weaknesses or past accidents reported for the same model. Moreover, it enables efficient decision-making processes, ensuring that only reliable and well-maintained equipment are deployed on critical infrastructure sites, thereby minimizing delays and enhancing overall project productivity.

The Role of VIN Search in Machinery Reliability

A Vehicle Identification Number (VIN) search is a powerful tool for heavy equipment operators and buyers to ensure the reliability and safety of machinery, which is paramount in today’s infrastructure development landscape. By conducting this search, stakeholders gain access to a wealth of information that extends beyond what’s visible on the surface. The process provides insights into the historical background of the equipment, including its manufacturing specifications and any maintenance or incident records. This data is invaluable for operators who need to make informed decisions about the condition and suitability of heavy machinery for their projects.

Moreover, as infrastructure projects expand, the need for reliable and safe equipment becomes more critical. A VIN search allows buyers to identify potential issues early on, whether it’s a known mechanical problem reported by previous owners or evidence of mishandling or accidents. This proactive approach to machinery assessment can significantly reduce downtime, enhance operational efficiency, and, most importantly, ensure worker safety. In essence, incorporating a VIN Structure Analysis into the procurement and operation process is a step towards fostering a culture of safety and quality in the heavy equipment industry.

In today’s expanding infrastructure landscape, reliable heavy equipment is paramount. Conducting a Heavy Equipment VIN Search has emerged as a game-changer for operators and buyers alike. By revealing detailed manufacturing information and incident history, this process empowers stakeholders to make informed decisions, enhancing safety and efficiency in every project. Embracing VIN Structure Analysis is not just beneficial; it’s essential for navigating the future of infrastructure development.